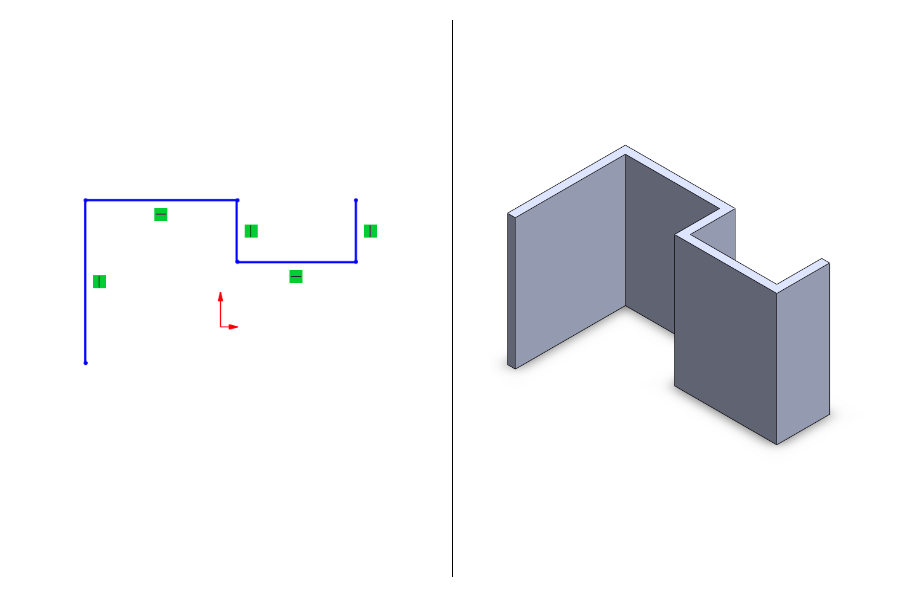

Extrude Thin (Thicken).

Extrude thin is a specialized feature in SolidWorks that allows users to create thin-walled parts by extruding a sketch along a path. This feature is particularly useful for designing sheet metal parts, enclosures, and other components that require a thin and lightweight construction.

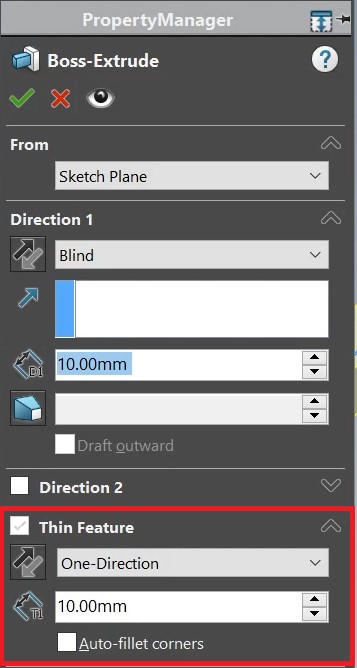

The extrude thin feature works similarly to the standard extrude feature, with the added option to specify the thickness of the extruded material. This thickness can be defined as a constant value or can vary along the length of the extrusion.

How Create Extrude Thin ?

Watch the short video for more clarity

Advantages

One of the main advantages of using the extrude thin feature is that it enables designers to create complex sheet metal parts with a high degree of accuracy and precision. By extruding the sketch along a path, designers can create intricate shapes and curves that would be difficult or impossible to achieve with traditional sheet metal fabrication methods.

Another advantage of the extrude thin feature is that it allows for easy modification and editing of the part geometry. Designers can easily adjust the thickness of the part, modify the shape of the sketch, and refine the overall design until it meets their exact specifications.

Summary

Overall, the extrude thin feature in SolidWorks offers a powerful and efficient way to create thin-walled parts with a high degree of precision and accuracy. Whether you are designing sheet metal parts, enclosures, or other thin-walled components, the extrude thin feature can help you achieve your design goals with ease and efficiency.